your partner in process plant data analytics CLICK TO SERVE YOU

About AKXA Tech

AKXA Tech Pvt. Ltd. is a technology driven industrial analytics company, initiated by technocrats with vast field experience in dealing with process plant equipment. This new technological venture promoted by Aqua Alloys Pvt. Ltd. is proudly associated with research team at IIT Madras and is proud to be an "IITM Incubated Company" and "StartUp India Approved company (DIPP 2649)". The main vision of the company is to develop and provide efficiency enhancing products and services to Process Plants.

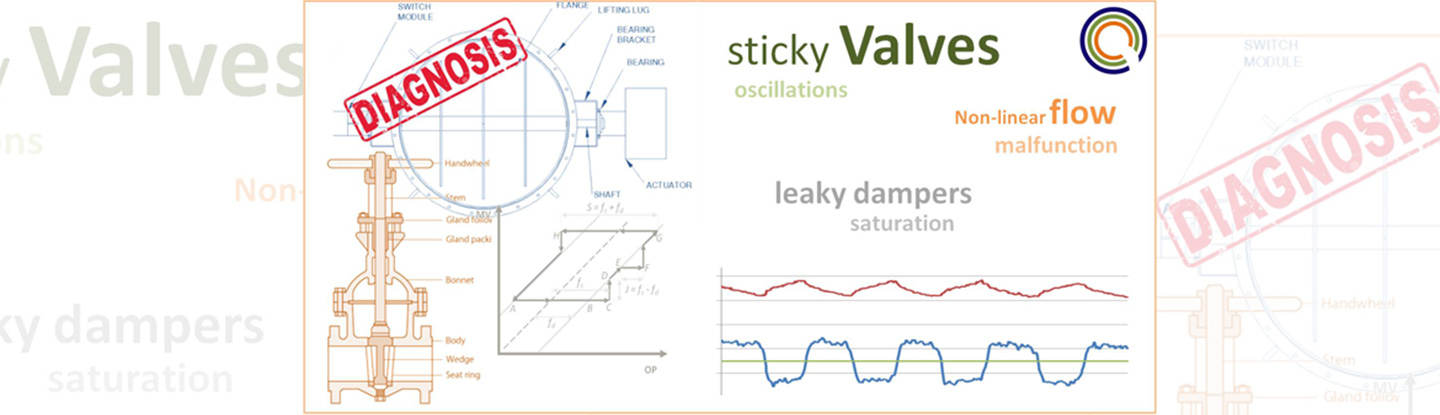

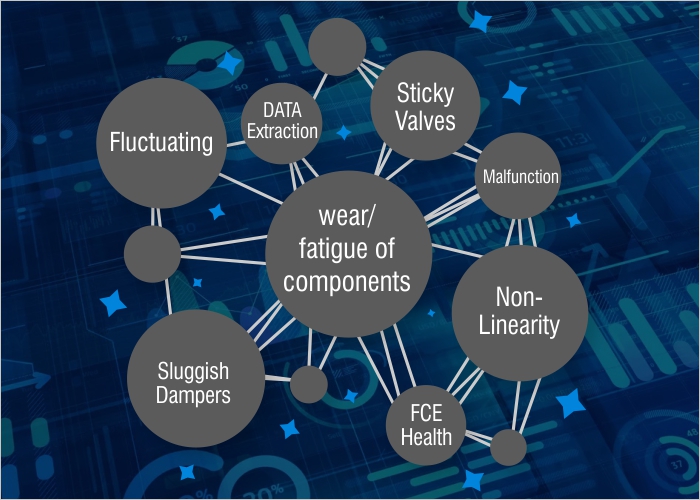

Aims to deliver solutions/data analytics tools which can systematically and automatically analyze the Historical Data from the plant DCS and create a Knowledge Resource out of it. AKXA products can Assist the decision makers in taking optimum decisions leading to enhanced asset utilization and productivity.

"performance monitoring,assessment and optimization of process control systems"was very insightful,practical and effective .

Problem identified,resolved and changes made in air flow circuit & mill internals,stabilization of auto feeding and water spraying system have contributed to overall improvement of 8% in the production and mill output.

We have changed the PID settings of Calciner temperature controller as well as Cooler Lane DP controller as per recommendations of M/S AKXATECH and we are satisfied with the above mentioned PID operations which has helped to improve stability in Kiln & cooler operations.